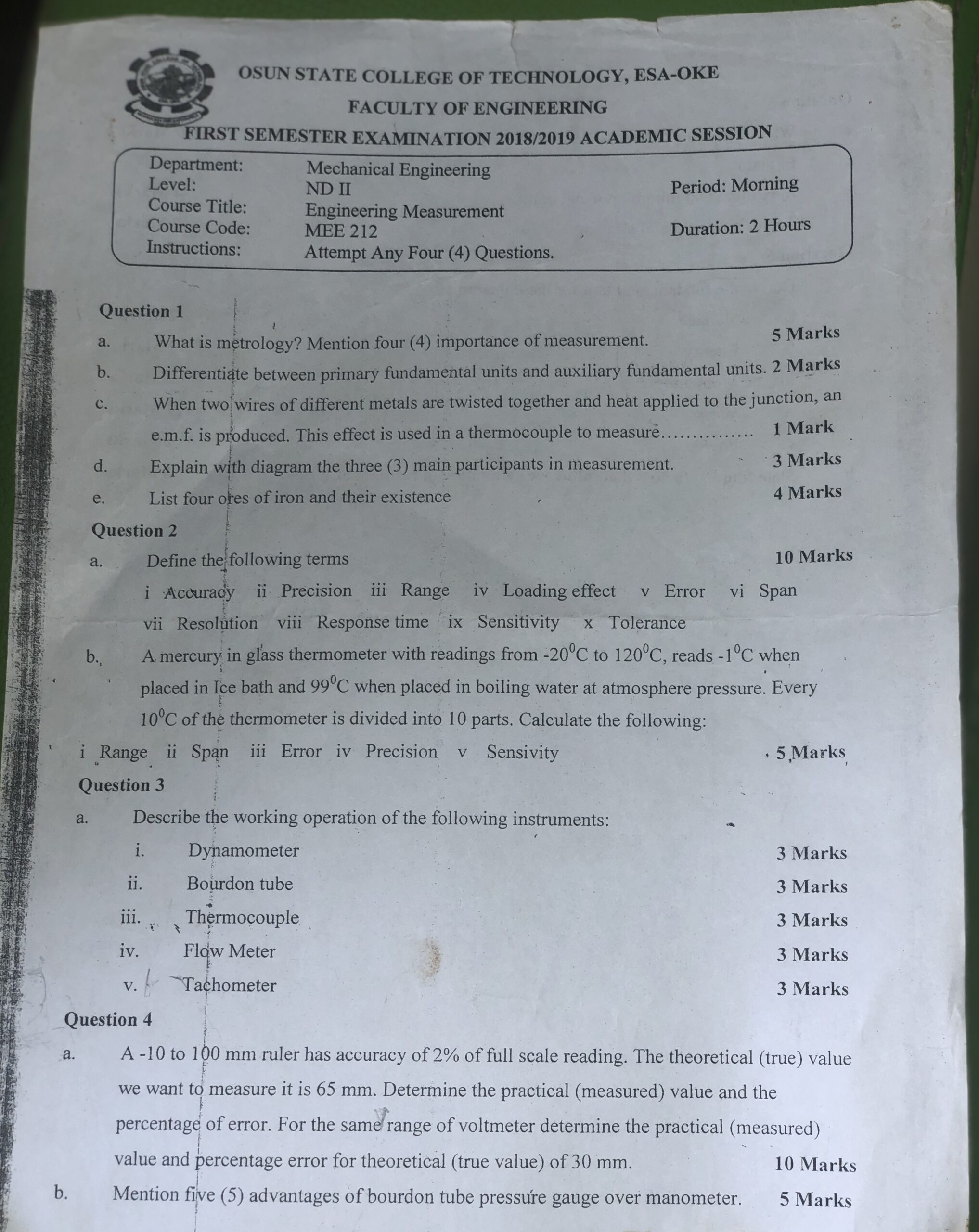

COURSE TITLE: Engineering Measurement

COURSE CODE: MEE 212

DURATION: 2 Hours

Instructions

Attempt Any Four (4) Questions.

Question 1(a): What is metrology? Mention four (4) importance of measurement.

Question 1(b): Differentiate between primary fundamental units and auxiliary fundamental units.

Question 1(c): When two wires of different metals are twisted together and heat applied to the junction, an e.m.f. is produced. This effect is used in a thermocouple to measure.

Question 1(d): Explain with diagram the three (3) main participants in measurement.

Question 1(e): List four ores of iron and their existence

Question 2(a): Define the following terms i Accuracy ii Precision iii Range iv Loading effect v Error vi Span vii Resolution viii Response time ix Sensitivity x Tolerance

Question 2(b): A mercury in glass thermometer with readings from -20°C to 120°C, reads -1°C when placed in Ice bath and 99°C when placed in boiling water at atmosphere pressure. Every 10°C of the thermometer is divided into 10 parts. Calculate the following: i Range ii Span iii Error iv Precision v Sensivity

Question 3: Describe the working operation of the following instruments: i. Dynamometer ii. Bourdon tube iii. Thermocouple iv. Flow Meter V. Tachometer

Question 4(a): A -10 to 100 mm ruler has accuracy of 2% of full scale reading. The theoretical (true) value we want to measure it is 65 mm. Determine the practical (measured) value and the percentage of error. For the same range of voltmeter determine the practical (measured) value and percentage error for theoretical (true value) of 30 mm.

Question 4(b): Mention five (5) advantages of bourdon tube pressure gauge over manometer.

Answers

Answer 1(a):

a. Metrology is the scientific study of measurement, focusing on accuracy, standardization, and reproducibility. Importance of Measurement:

a. Metrology is the scientific study of measurement, focusing on accuracy, standardization, and reproducibility. Importance of Measurement:

- Ensures quality control in manufacturing.

- Facilitates international trade through standardized units.

- Enables scientific research and innovation.

- Enhances safety in engineering applications.

Answer 1(b):

b.

b.

- Primary Fundamental Units: Base SI units (e.g., meter, kilogram, second).

- Auxiliary Fundamental Units: Supplementary or derived units (e.g., newton, pascal, radian).

Answer 1(c):

c. The described effect is the Seebeck effect, used in thermocouples to measure temperature.

c. The described effect is the Seebeck effect, used in thermocouples to measure temperature.

Answer 1(d):

d. Three Main Participants in Measurement:

d. Three Main Participants in Measurement:

- Sensor/Transducer (converts physical quantity to measurable signal).

- Signal Conditioner (amplifies/filters the signal).

- Display/Recorder (shows or records the result). (Diagram would show these components in sequence.)

Answer 1(e):

e. Iron Ores:

e. Iron Ores:

- Hematite (Fe₂O₃) – sedimentary rocks.

- Magnetite (Fe₃O₄) – igneous/metamorphic rocks.

- Limonite (FeO(OH)·nH₂O) – weathered zones.

- Siderite (FeCO₃) – hydrothermal veins.

Answer 2(a):

a. Definitions:

a. Definitions:

- Accuracy: Closeness of a measurement to the true value.

- Precision: Consistency of repeated measurements.

- Range: Interval between minimum and maximum measurable values.

- Loading Effect: Disturbance caused by the instrument on the system.

- Error: Difference between measured and true values.

- Span: Difference between upper and lower range limits.

- Resolution: Smallest detectable change in measurement.

- Response Time: Time to reach 95% of the final value.

- Sensitivity: Output change per unit input change.

- Tolerance: Permissible deviation from a specified value.

Answer 2(b):

b. Calculations:

b. Calculations:

- Range: -20°C to 120°C.

- Span: 120−(−20)=140∘C.

- Error: At 0°C: −1∘C; at 100°C: −1∘C. Average error = −1∘C.

- Precision: 1∘C (smallest division).

- Sensitivity: 1∘C per division.

Answer 3:

Working Operations:

Working Operations:

- Dynamometer: Measures torque/power by absorbing or transmitting energy (e.g., prony brake).

- Bourdon Tube: Curved tube straightens under pressure, moving a pointer via gears.

- Thermocouple: Generates voltage from temperature differences (Seebeck effect).

- Flow Meter: Measures flow rate via differential pressure (orifice) or turbine rotation.

- Tachometer: Measures rotational speed using magnetic or optical sensors.

Answer 4(a):

- Full Scale (FS): 100−(−10)=110 mm.

- Accuracy: 2%×110=±2.2 mm.

For 65 mm:

- Measured Value: 65±2.2 mm (range: 62.8 mm to 67.2 mm).

- % Error: 2.265×100≈3.38%.

For 30 mm:

- Measured Value: 30±2.2 mm (range: 27.8 mm to 32.2 mm).

- % Error: 2.230×100≈7.33%.

Answer 4(b):

b. Advantages of Bourdon Tube over Manometer:

b. Advantages of Bourdon Tube over Manometer:

- Compact and portable.

- No risk of fluid leakage.

- Suitable for high-pressure applications.

- Easier to read (direct pointer display).

- Minimal maintenance required.

Note: Diagrams for Question 1d and instrument workings (Question 3) are conceptual and require visual representation.