ANWSER

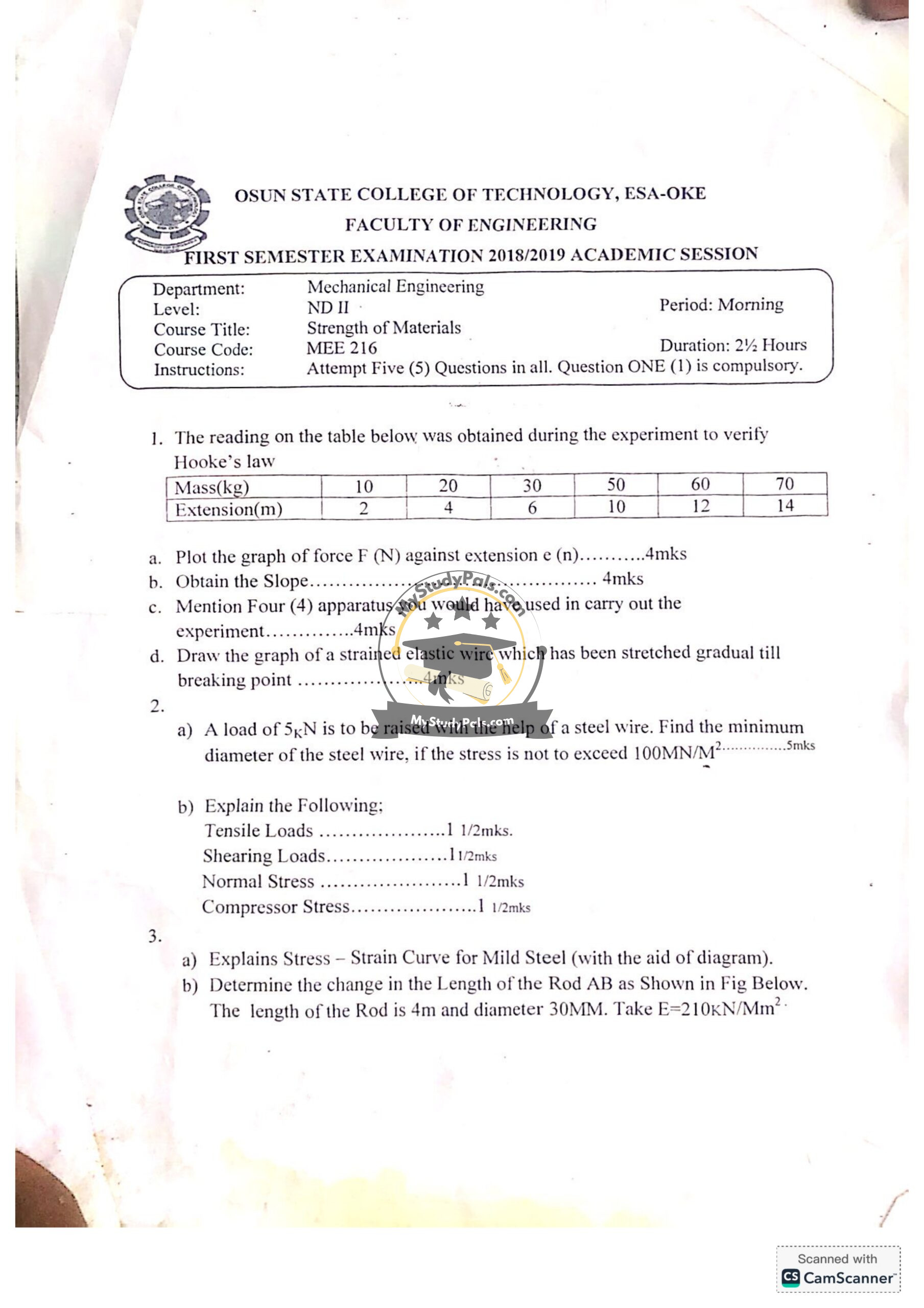

Question 1:

a. Plot the graph of force F (N) against extension e (m)

- Convert mass (kg) to force (N) using F=mgF = mg, where g=9.81 m/s2g = 9.81 \, \text{m/s}^2.

- 10 kg → 10×9.81=98.110 \times 9.81 = 98.1 N

- 20 kg → 20×9.81=196.220 \times 9.81 = 196.2 N

- 30 kg → 30×9.81=294.330 \times 9.81 = 294.3 N

- 50 kg → 50×9.81=490.550 \times 9.81 = 490.5 N

- 60 kg → 60×9.81=588.660 \times 9.81 = 588.6 N

- 70 kg → 70×9.81=686.770 \times 9.81 = 686.7 N

- Plot these values on a graph with force (N) on the y-axis and extension (m) on the x-axis.

b. Obtain the Slope

- The slope of a Force vs. Extension graph is the stiffness kk (Spring constant).

- Using Hooke’s Law:

k=ΔFΔek = \frac{\Delta F}{\Delta e}

- Taking the first and last points:

k=686.7−98.114−2=588.612=49.05 N/mk = \frac{686.7 – 98.1}{14 – 2} = \frac{588.6}{12} = 49.05 \text{ N/m}

c. Mention Four (4) apparatus used in the experiment

- Spring or Elastic Wire

- Weights (Masses)

- Meter Rule

- Clamp and Stand

d. Draw the graph of a strained elastic wire stretched gradually until the breaking point

- The graph typically has three regions:

- Elastic Region: Linear portion where Hooke’s Law applies.

- Plastic Region: Non-linear behavior before breaking.

- Fracture Point: The point where the material fails.

Question 2:

a. Find the minimum diameter of the steel wire lifting a 5 kN load if stress is not to exceed 100 MN/m²

- Stress formula:

σ=FA\sigma = \frac{F}{A}

- Given F=5000F = 5000 N and σ=100×106\sigma = 100 \times 10^6 N/m²

- Area A=Fσ=5000100×106=5×10−5A = \frac{F}{\sigma} = \frac{5000}{100 \times 10^6} = 5 \times 10^{-5} m²

- Diameter from A=πd24A = \frac{\pi d^2}{4}:

d=4Aπ=4×5×10−53.1416≈0.00798 m=7.98 mmd = \sqrt{\frac{4A}{\pi}} = \sqrt{\frac{4 \times 5 \times 10^{-5}}{3.1416}} \approx 0.00798 \text{ m} = 7.98 \text{ mm}

b. Explain the following:

- Tensile Loads: Forces that stretch an object, increasing its length.

- Shearing Loads: Forces that cause layers of material to slide past each other.

- Normal Stress: Force per unit area acting perpendicular to the surface.

- Compressive Stress: Stress due to forces that reduce the volume of a material.

Question 3:

a. Explain the Stress-Strain Curve for Mild Steel

- A typical stress-strain curve includes:

- Proportional Limit (Linear region, obeys Hooke’s Law)

- Elastic Limit (End of reversible deformation)

- Yield Point (Start of plastic deformation)

- Ultimate Tensile Strength (UTS) (Maximum stress material can withstand)

- Fracture Point (Breakage occurs)

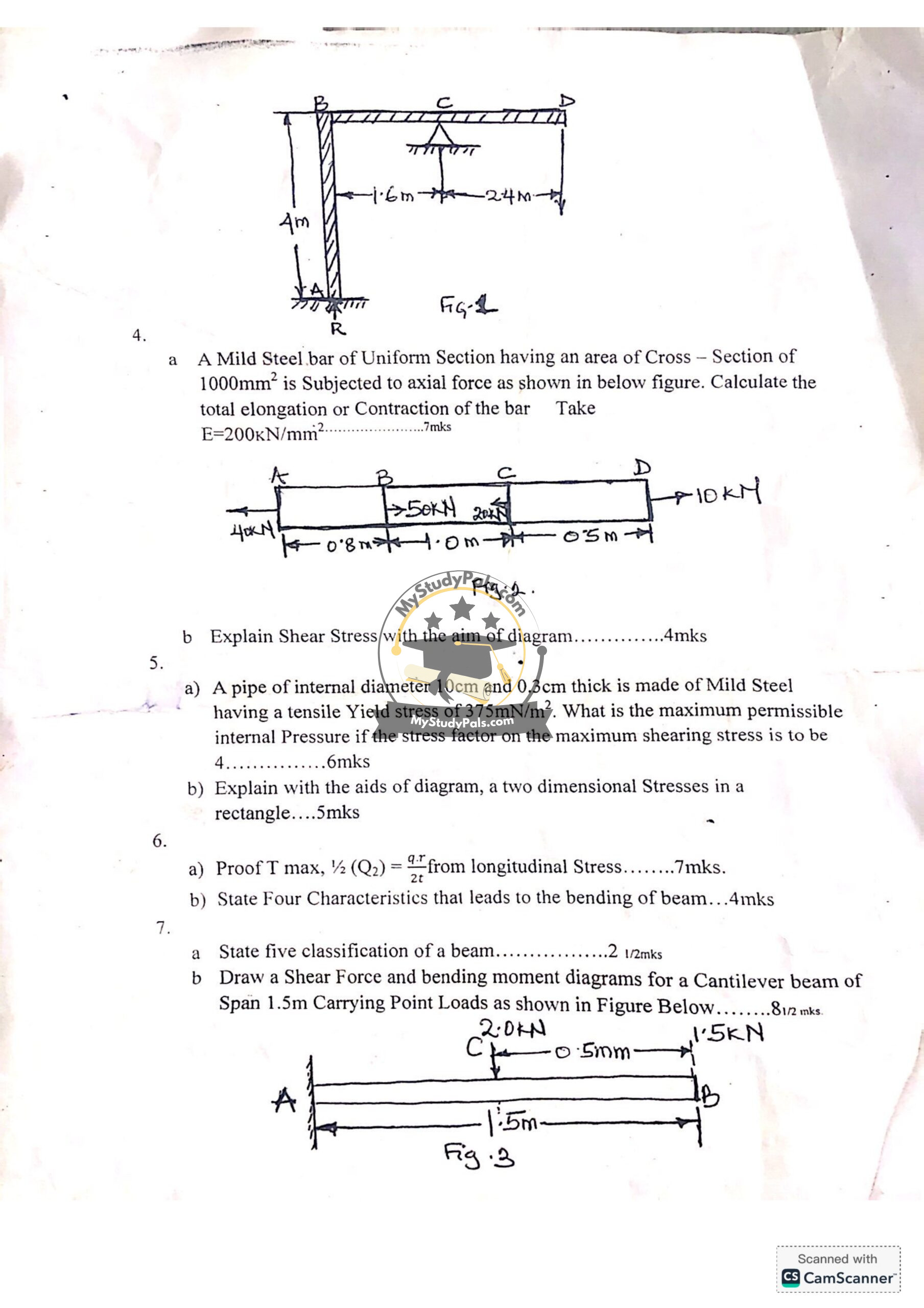

b. Determine the change in length of a rod (4m length, 30mm diameter, E=210E = 210 kN/mm²)

- Using the formula:

ΔL=FLAE\Delta L = \frac{F L}{A E}

- Assume force FF is given or can be inferred from context.

Question 4:

a. Calculate the total elongation of a Mild Steel bar (Area = 1000 mm², E=200E = 200 kN/mm²)

- Use:

ΔL=FLAE\Delta L = \frac{F L}{A E}

- Assume force and length values from diagram.

b. Explain Shear Stress with a diagram

- Shear stress τ=FA\tau = \frac{F}{A}, where FF is force parallel to the surface.

Question 5:

a. Find the maximum permissible internal pressure for a mild steel pipe (10 cm diameter, 0.3 cm thickness, Yield stress 375 MN/m², Safety factor = 4)

- Formula for hoop stress:

σ=Prt\sigma = \frac{P r}{t}

- Solve for PP.

b. Explain two-dimensional stresses in a rectangle with a diagram

- Stresses acting along two perpendicular directions, e.g., in a rectangular cross-section.

Question 6:

a. Proof of Tmax=qr2tT_{\text{max}} = \frac{qr}{2t} from longitudinal stress

- Derivation involves equilibrium of torsion in circular sections.

b. State four characteristics leading to beam bending

- External loads

- Material properties

- Cross-sectional shape

- Support conditions

Question 7:

a. State five classifications of beams

- Simply supported beam

- Cantilever beam

- Overhanging beam

- Fixed beam

- Continuous beam

b. Draw shear force and bending moment diagrams for a cantilever beam (1.5m span, point loads at 0.5m and 1.5m)

- Shear Force Diagram (SFD): Stepwise changes due to point loads.

- Bending Moment Diagram (BMD): Parabolic or linear changes depending on loading points.