ANWSER

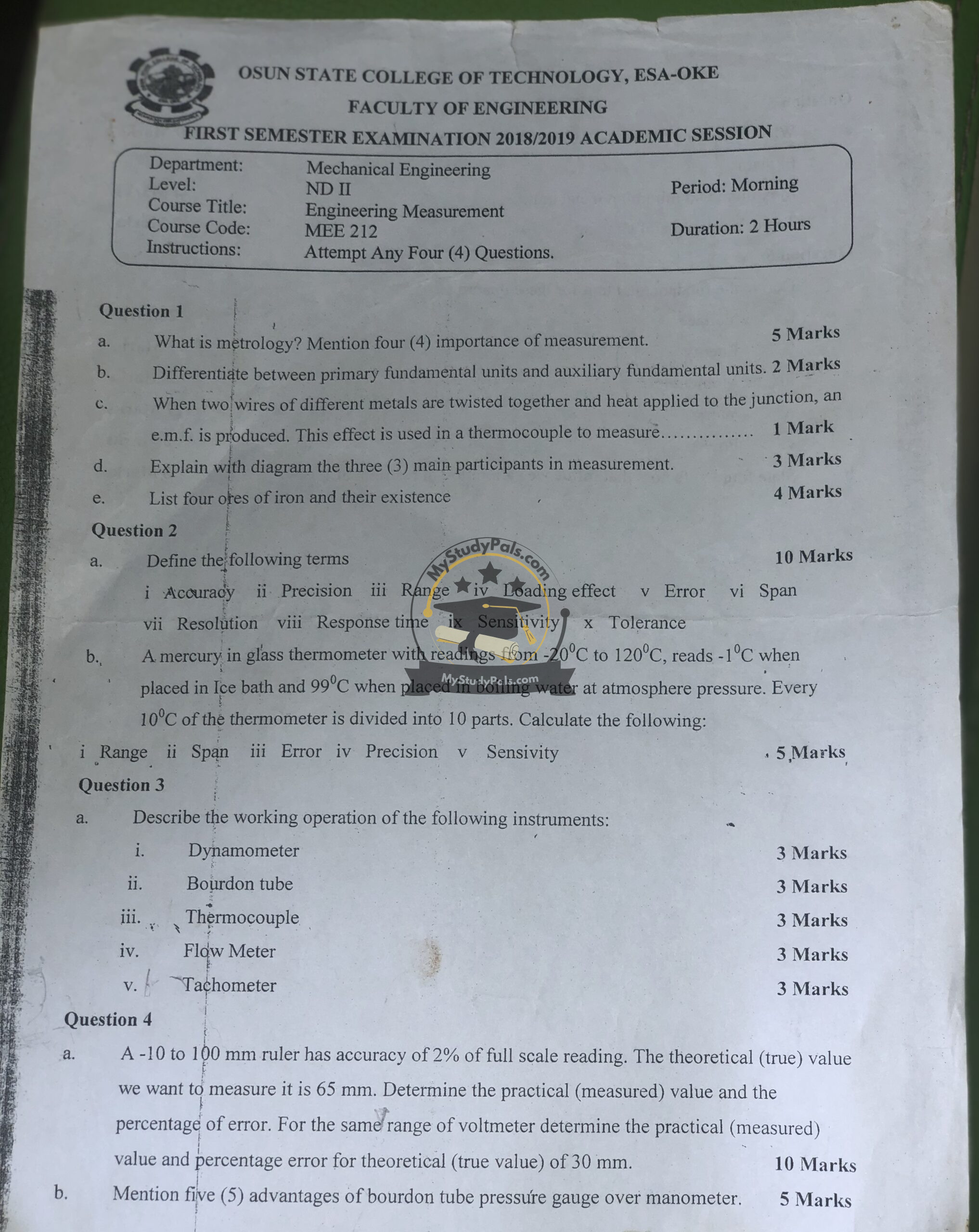

Question 1:

a. Metrology is the science of measurement.

Importance of measurement:

- Ensures accuracy and reliability in engineering processes.

- Facilitates quality control in manufacturing.

- Helps in standardization of products and processes.

- Enables proper calibration of instruments.

b.

- Primary fundamental units: These are base units that are independent of other units (e.g., meter, kilogram, second, ampere).

- Auxiliary fundamental units: These are derived units that assist in expressing measurements but are not base units themselves (e.g., radians for angles, steradians for solid angles).

c. Thermoelectric Effect

When two wires of different metals are twisted together and heat is applied to the junction, an electromotive force (e.m.f) is produced. This effect is used in a thermocouple to measure temperature.

d. Participants in measurement:

- Measurand – The quantity being measured.

- Measuring instrument – The device used for measurement.

- Observer – The person analyzing and recording the measurement.

(Diagram should illustrate these three participants.)

e. Ores of Iron and Their Existence:

- Hematite (Fe₂O₃) – Found in sedimentary rocks.

- Magnetite (Fe₃O₄) – Found in igneous and metamorphic rocks.

- Limonite (FeO(OH)·nH₂O) – Found in marshy regions.

- Siderite (FeCO₃) – Found in hydrothermal veins.

Question 2:

a. Define the following terms:

- Accuracy – The degree of closeness of a measured value to the actual (true) value.

- Precision – The consistency of repeated measurements under unchanged conditions.

- Range – The difference between the maximum and minimum values a measuring instrument can record.

- Loading effect – The impact of the measuring instrument on the circuit or system it is measuring.

- Error – The deviation of the measured value from the actual (true) value.

- Span – The difference between the highest and lowest values an instrument can measure.

- Resolution – The smallest change an instrument can detect.

- Response time – The time taken by an instrument to stabilize after a change in input.

- Sensitivity – The ratio of change in output to change in input.

- Tolerance – The allowable deviation from a specified value.

b. Thermometer Readings Calculation

- Given:

- Thermometer range: -20°C to 120°C

- Ice bath reading: -1°C

- Boiling water reading: 99°C

- Each 10°C division is marked into 10 parts (1°C per division).

Calculations:

- Range = Max value – Min value = 120°C – (-20°C) = 140°C.

- Span = Difference between highest and lowest readings = 120°C – (-20°C) = 140°C.

- Error = Theoretical value – Measured value = 0°C – (-1°C) = 1°C.

- Precision = Smallest unit measurable = 1°C per division.

- Sensitivity = Output change/Input change = 1/10 = 0.1 units per degree.

Question 3:

a. Describe the working operation of the following instruments:

- Dynamometer – Measures force, torque, or power. Uses strain gauges or springs to determine mechanical force based on deformation.

- Bourdon Tube – Measures pressure using a coiled tube that straightens when pressure increases. The motion is transmitted to a dial gauge.

- Thermocouple – Measures temperature by producing a voltage when heat is applied to the junction of two different metals.

- Flow Meter – Measures the rate of fluid flow using various principles like differential pressure, electromagnetic induction, or ultrasonic waves.

- Tachometer – Measures rotational speed (RPM) of a shaft or disk using mechanical, optical, or digital sensors.

Question 4:

a. Measurement Accuracy Calculation

- Given:

- Full-scale accuracy = 2%

- Ruler measurement range = -10 mm to 100 mm (110 mm total)

- True value = 65 mm

Error Calculation:

- Full-scale error = 2%×1102\% \times 110 mm = 2.2 mm

- Practical measured value = True value ± Full-scale error

- Measured value = 65 mm ± 2.2 mm

- Possible range = 62.8 mm to 67.2 mm

- Percentage error = Full-scale errorTrue value×100\frac{\text{Full-scale error}}{\text{True value}} \times 100

= 2.265×100\frac{2.2}{65} \times 100

= 3.38%

For a voltmeter (30 mm true value):

- Full-scale error = 2.2 mm (same as above)

- Measured value range = 27.8 mm to 32.2 mm

- Percentage error = 2.230×100\frac{2.2}{30} \times 100 = 7.33%

b. Five advantages of Bourdon Tube over Manometer:

- Can measure both high and low pressures accurately.

- More compact and easier to handle.

- Provides direct pressure readings without requiring external fluids.

- More durable and resistant to environmental factors.

- Can be integrated into automated systems for continuous monitoring.