ANSWER

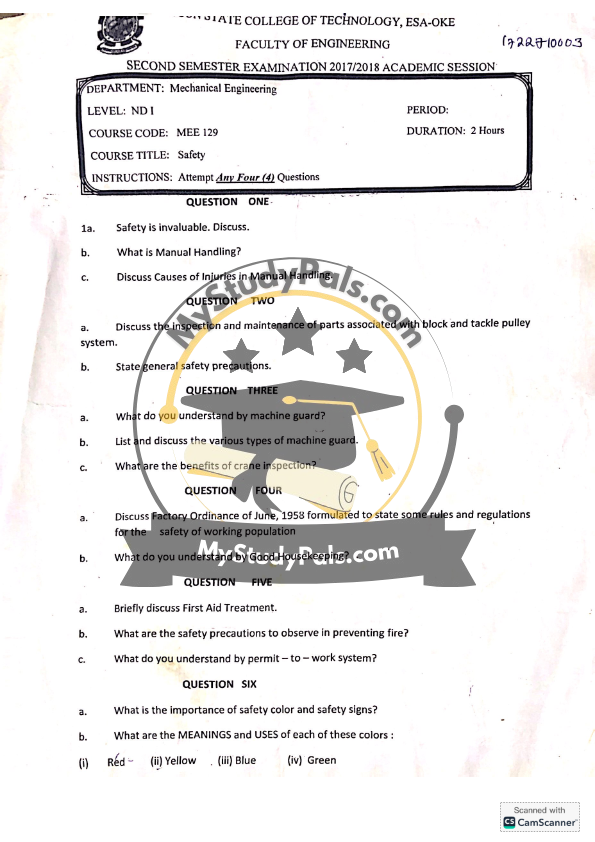

Question 1:

a. Safety is invaluable. Discuss.

Safety is invaluable because it ensures the well-being of individuals, prevents accidents, and protects lives and property. Implementing proper safety measures minimizes risks and reduces workplace injuries, leading to increased productivity and efficiency. Safety also reduces financial losses associated with medical expenses, equipment damage, and legal liabilities.

b. What is Manual Handling?

Manual handling refers to the process of lifting, carrying, pushing, pulling, or moving objects by hand or bodily force. It includes activities such as lifting heavy loads, stacking items, and repetitive movements. Proper manual handling techniques help prevent injuries such as muscle strains, back pain, and fractures.

c. Discuss Causes of Injuries in Manual Handling.

- Poor Lifting Techniques – Lifting with a bent back or incorrect posture.

- Excessive Load Weight – Lifting objects beyond personal capability.

- Repetitive Movements – Continuous lifting or bending without rest.

- Slippery or Uneven Surfaces – Increases the risk of slips, trips, and falls.

- Insufficient Training – Lack of knowledge on proper handling techniques.

Question 2:

a. Discuss the inspection and maintenance of parts associated with the block and tackle pulley system.

Inspection and maintenance of block and tackle pulley systems involve:

- Visual Inspection – Checking for worn-out ropes, cracks, or misalignment.

- Lubrication – Ensuring smooth movement of pulleys and gears.

- Load Testing – Verifying that the system can handle required loads.

- Checking Fastenings – Ensuring bolts and nuts are secure.

- Replacing Worn-out Parts – Timely replacement of damaged components.

b. State general safety precautions.

- Use personal protective equipment (PPE).

- Keep work areas clean and organized.

- Follow proper lifting techniques.

- Ensure proper ventilation in enclosed spaces.

- Use safety signs and warnings where necessary.

- Conduct regular safety training and drills.

Question 3:

a. What do you understand by machine guard?

A machine guard is a protective device designed to shield workers from moving parts, flying debris, and accidental contact with dangerous machine components. It enhances safety by preventing injuries such as cuts, amputations, and burns.

b. List and discuss the various types of machine guards.

- Fixed Guards – Permanently attached to machinery, preventing access to hazardous parts.

- Interlocked Guards – Automatically shuts off machines when opened.

- Adjustable Guards – Can be repositioned to accommodate different tasks.

- Self-Adjusting Guards – Moves as needed to provide protection while allowing work.

c. What are the benefits of crane inspection?

- Prevents Accidents – Detects potential mechanical failures.

- Ensures Compliance – Meets workplace safety regulations.

- Prolongs Equipment Life – Identifies worn-out parts for replacement.

- Enhances Efficiency – Reduces downtime due to unexpected breakdowns.

Question 4:

a. Discuss Factory Ordinance of June, 1958 formulated to state some rules and regulations for the safety of the working population.

The Factory Ordinance of June 1958 was established to ensure workplace safety by mandating:

- Proper ventilation and lighting in factories.

- Safe operation of machines with guards.

- Fire prevention measures.

- Provision of protective equipment.

- Regular safety inspections and maintenance.

b. What do you understand by Good Housekeeping?

Good housekeeping refers to maintaining cleanliness and order in the workplace to prevent accidents. It includes:

- Proper waste disposal.

- Keeping floors free from spills and obstructions.

- Organizing tools and equipment properly.

- Ensuring emergency exits are unobstructed.

Question 5:

a. Briefly discuss First Aid Treatment.

First Aid Treatment involves providing immediate medical assistance to an injured or ill person before professional help arrives. It includes:

- Stopping Bleeding – Applying pressure to wounds.

- Treating Burns – Cooling the affected area with water.

- CPR (Cardiopulmonary Resuscitation) – Assisting individuals with breathing difficulties.

- Immobilizing Fractures – Using splints to stabilize broken bones.

b. What are the safety precautions to observe in preventing fire?

- Store flammable materials properly.

- Keep fire extinguishers in accessible locations.

- Avoid overloading electrical sockets.

- Train employees in fire safety procedures.

- Ensure proper ventilation to prevent the buildup of flammable gases.

c. What do you understand by permit-to-work system?

A permit-to-work system is a safety measure that requires formal authorization before conducting hazardous tasks such as working in confined spaces, electrical maintenance, or handling hazardous chemicals. It ensures risk assessment and compliance with safety protocols.

Question 6:

a. What is the importance of safety color and safety signs?

Safety colors and signs help in:

- Alerting workers to hazards.

- Guiding safe actions and responses.

- Preventing accidents and injuries.

- Enhancing compliance with safety regulations.

b. What are the MEANINGS and USES of each of these colors?

- Red – Indicates danger or prohibition (e.g., fire extinguishers, stop signs).

- Yellow – Warns of potential hazards (e.g., slippery floors, caution signs).

- Blue – Provides mandatory instructions (e.g., wear PPE signs).

- Green – Indicates safety and emergency equipment (e.g., first aid stations, exits).