ANWSER

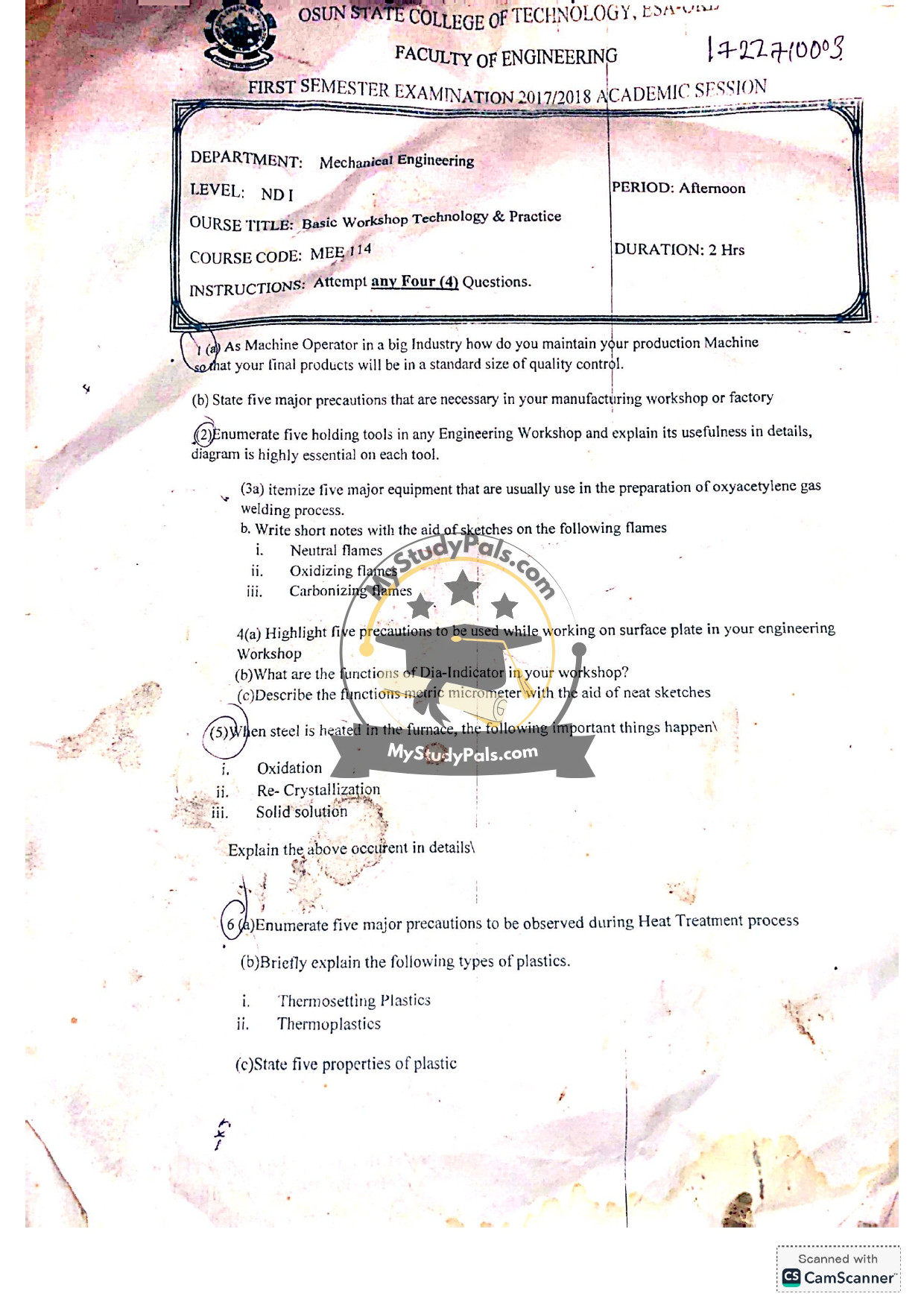

Question 1(a):

To maintain production machines for standard size and quality control, a machine operator should:

1. Perform regular lubrication to reduce friction and wear.

2. Calibrate machines periodically to ensure dimensional accuracy.

3. Inspect and replace worn-out parts (e.g., belts, bearings) to prevent defects.

4. Clean machines to avoid debris buildup affecting product quality.

5. Use quality raw materials to minimize machine strain and inconsistencies.

6. Conduct routine quality checks (e.g., sample measurements) during production.

Question 1(b):

Five major workshop precautions:

1. Wear personal protective equipment (PPE) like safety goggles and gloves.

2. Ensure machine guards are in place to prevent accidents.

3. Keep the workspace clean and organized to avoid tripping hazards.

4. Follow lockout-tagout procedures during maintenance.

5. Store flammable materials away from heat sources to prevent fires.

—

Question 2:

Five holding tools and their uses:

1. Bench Vice: Clamps workpieces securely for drilling, filing, or cutting.

– *Diagram*: Fixed jaw, movable jaw, handle for tightening.

2. C-Clamp: Holds materials firmly to a workbench during welding or assembly.

– *Diagram*: C-shaped frame with a screw mechanism.

3. Pliers: Grips small components or bends wires.

– *Diagram*: Two handles, pivot point, and serrated jaws.

4. Angle Plate: Ensures workpieces are held at 90° for accurate machining.

– *Diagram*: L-shaped metal block with clamping holes.

5. Bench Dogs: Pegs inserted into workbench holes to secure wooden workpieces.

– *Diagram*: Cylindrical metal or wooden pegs with a spring mechanism.

—

Question 3(a):

Equipment for oxyacetylene welding:

1. Oxygen and acetylene cylinders.

2. Pressure regulators.

3. Welding torch with mixing chamber.

4. Hoses (oxygen: green; acetylene: red).

5. Spark lighter or friction igniter.

Question 3(b):

Flame types:

1. Neutral Flame: Balanced oxygen-acetylene ratio (1:1).

– *Sketch*: Bright inner cone + blue outer flame. Used for welding steel.

2. Oxidizing Flame: Excess oxygen (hissing sound).

– *Sketch*: Short inner cone. Suitable for brass or bronze.

3. Carburizing Flame: Excess acetylene (feathery outer flame).

– *Sketch*: Longer inner cone. Used for welding nickel or cast iron.

—

Question 4(a):

Surface plate precautions:

1. Clean the plate with a lint-free cloth before use.

2. Avoid hammering or dropping tools on the plate.

3. Lift heavy objects properly to prevent scratching.

4. Do not overload the plate beyond its capacity.

5. Check flatness regularly with a precision straightedge.

Question 4(b):

Dial Indicator functions:

– Measures small linear displacements (e.g., shaft runout, alignment errors).

– Used in quality control to ensure machinery tolerances.

Question 4(c):

Metric Micrometer:

– Measures dimensions up to 0.01mm accuracy.

– *Parts*: Frame, anvil (fixed), spindle (movable), sleeve (main scale), thimble (vernier scale), ratchet for controlled tightening.

– *Sketch*: U-shaped frame with calibrated scales.

—

Question 5:

Steel heating effects:

1. Oxidation: Formation of iron oxide (scale) due to reaction with oxygen, reducing material quality.

2. Recrystallization: Cold-worked grains reform into strain-free grains, improving ductility.

3. Solid Solution: Alloying elements (e.g., carbon) dissolve into the iron matrix, enhancing strength.

—

Question 6(a):

Heat treatment precautions:

1. Use calibrated thermostats for temperature control.

2. Avoid overheating to prevent grain growth.

3. Quench in the correct medium (oil, water, air) based on material.

4. Wear heat-resistant PPE (gloves, aprons).

5. Follow specified cooling rates to avoid cracking.

Question 6(b):

1. Thermosetting Plastics: Harden permanently when heated (e.g., epoxy, Bakelite). Cannot be remelted.

2. Thermoplastics: Soften when heated and harden when cooled (e.g., PVC, polyethylene). Recyclable.

Question 6(c):

Plastic properties:

1. Lightweight.

2. Corrosion-resistant.

3. Electrical insulators.

4. Low thermal conductivity.

5. Moldable under heat (thermoplastics).