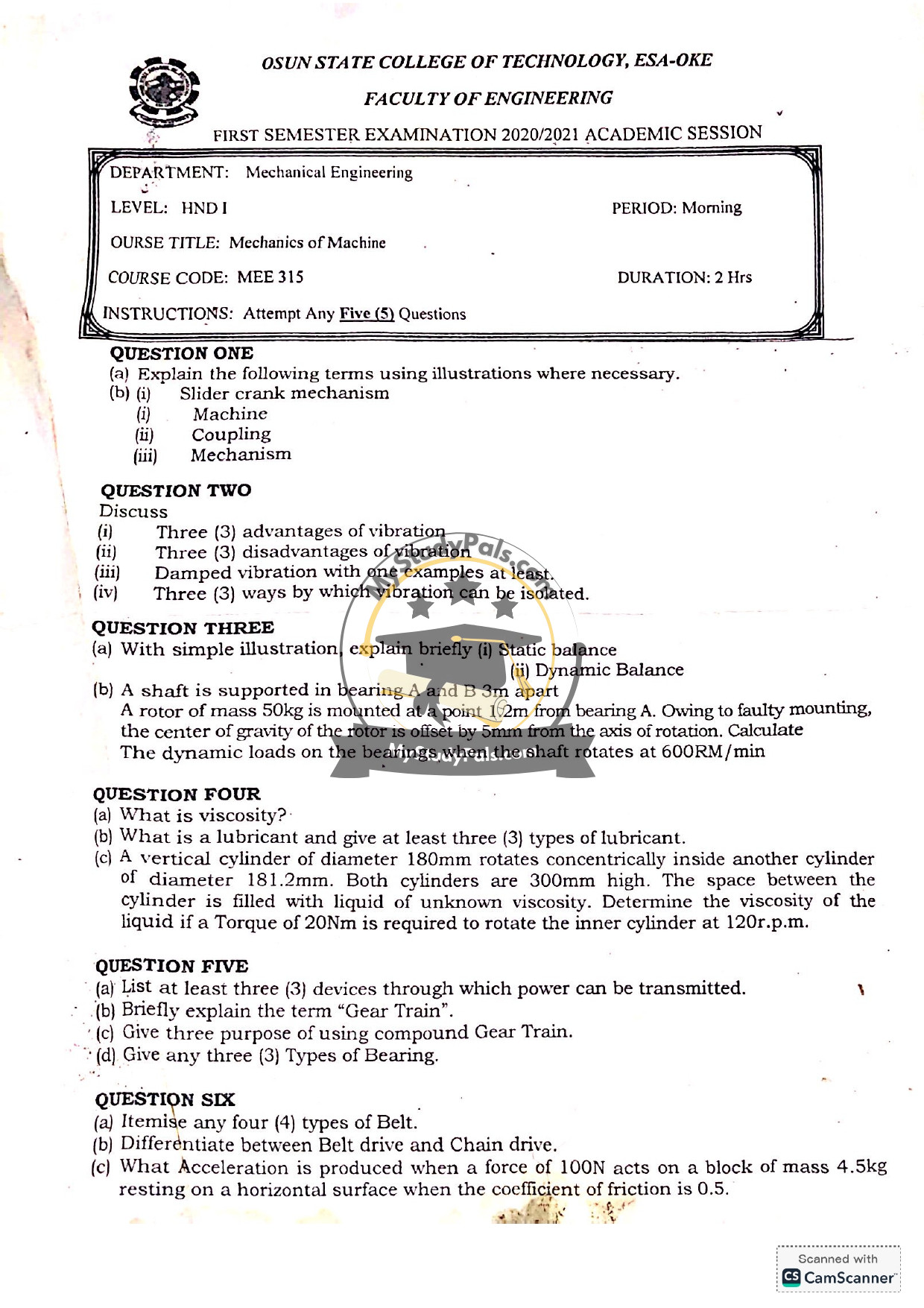

ANWSER

Question 1:

(i) Slider Crank Mechanism:

A mechanical system converting linear motion to rotational motion (or vice versa). Consists of a crank, connecting rod, and slider. Example: Piston engine.

(ii) Machine:

A device using energy to perform tasks via mechanisms. Examples: Engines, pumps.

(iii) Coupling:

Connects two shafts to transmit power, allowing misalignment. Types: Rigid, flexible.

(iv) Mechanism:

Parts working together to transform motion/force. Examples: Gears, linkages.

—

Question 2:

(i) Advantages of Vibration:

1. Used in vibrating screens for material sorting.

2. Ultrasonic cleaning.

3. Massage devices.

(ii) Disadvantages of Vibration:

1. Causes wear and tear.

2. Noise pollution.

3. Structural damage risk.

(iii) Damped Vibration:

Vibration energy dissipates over time. Example: Car shock absorbers.

(iv) Vibration Isolation Methods:

1. Rubber mounts.

2. Spring isolators.

3. Damping pads.

—

Question 3:

(a)

– Static Balance: Center of mass aligns with rotation axis (no rotation when stationary). Example: Balanced wheel.

– Dynamic Balance: No unbalanced forces during rotation. Example: Car tire balancing.

(b) Dynamic Load Calculation:

– Angular velocity: \( \omega = \frac{2\pi \times 600}{60} = 62.83 \, \text{rad/s} \).

– Centrifugal force: \( F = 50 \times 0.005 \times (62.83)^2 \approx 987 \, \text{N} \).

– Bearing reactions:

– \( R_B = \frac{987 \times 1.2}{3} \approx 394.8 \, \text{N} \).

– \( R_A = 987 – 394.8 \approx 592.2 \, \text{N} \).

Answer: Dynamic loads: \( R_A = 592.2 \, \text{N}, \, R_B = 394.8 \, \text{N} \).

—

Question 4:

(a) Viscosity: Fluid’s resistance to flow.

(b) Lubricant: Reduces friction. Types: Oil, grease, solid (graphite).

(c) Viscosity Calculation:

– \( \omega = 12.566 \, \text{rad/s}, \, T = 20 \, \text{Nm} \).

– Formula: \( \mu = \frac{T (r_2 – r_1)}{2\pi \omega r_1^3 h} \).

– Result: \( \mu \approx 0.694 \, \text{Pa·s} \).

—

Question 5:

(a) Power Transmission Devices: Belts, chains, gears.

(b) Gear Train: Gears transmitting power between shafts, altering speed/torque.

(c) Compound Gear Train Purposes:

1. High speed reduction.

2. Transmit power over distances.

3. Change rotation direction.

(d) Bearing Types: Ball, roller, plain bearings.

—

Question 6:

(a) Belt Types: Flat, V-belt, timing, round.

(b) Belt vs. Chain Drive:

– Belt: Quiet, slips, flexible.

– Chain: No slip, efficient, requires lubrication.

(c) Acceleration Calculation:

– Friction force: \( 0.5 \times 4.5 \times 9.81 \approx 22.07 \, \text{N} \).

– Net force: \( 100 – 22.07 = 77.93 \, \text{N} \).

– Acceleration: \( \frac{77.93}{4.5} \approx 17.32 \, \text{m/s}^2 \).

Answer: \( 17.32 \, \text{m/s}^2 \).