ANWSER

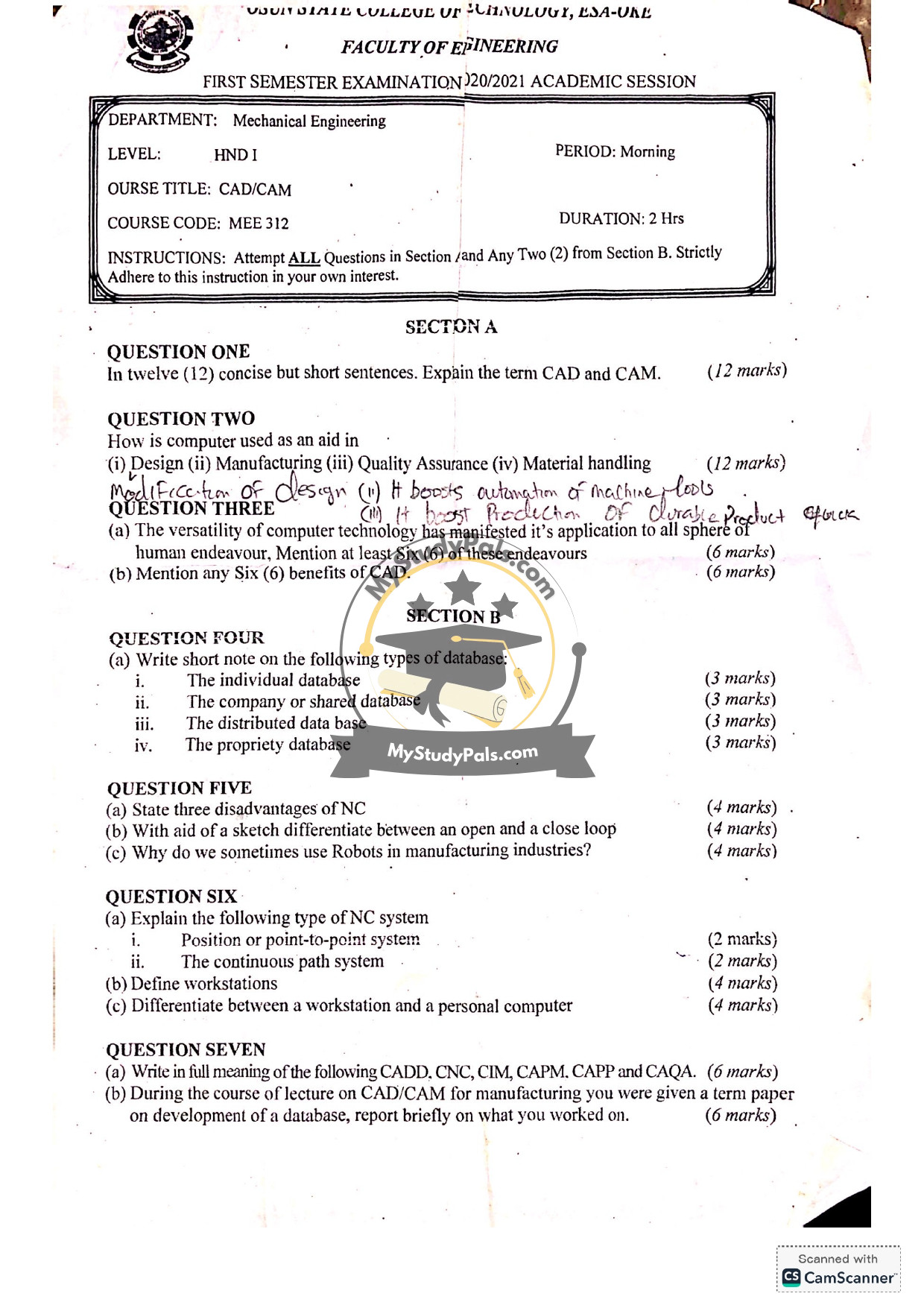

Question 1:

In twelve (12) concise but short sentences, explain the term CAD and CAM.

Answer:

1. CAD stands for Computer-Aided Design, which involves using computers to create, modify, and optimize designs.

2. CAM stands for Computer-Aided Manufacturing, which uses computers to control and automate manufacturing processes.

3. CAD allows engineers to create detailed 2D or 3D models of products.

4. CAM translates CAD designs into instructions for machines like CNC mills or lathes.

5. CAD improves design accuracy and reduces human errors.

6. CAM increases production efficiency by automating repetitive tasks.

7. CAD enables easy modification and iteration of designs.

8. CAM reduces material waste by optimizing tool paths.

9. CAD software includes tools for simulation and analysis of designs.

10. CAM integrates with other systems like robotics for seamless production.

11. CAD files can be shared digitally, facilitating collaboration.

12. Together, CAD and CAM streamline the transition from design to production.

—

Question 2:

How is the computer used as an aid in:

(i) Design (ii) Manufacturing (iii) Quality Assurance (iv) Material handling

Answer:

(i) Design: Computers are used to create, visualize, and simulate designs using CAD software, enabling precision, easy modifications, and virtual testing.

(ii) Manufacturing: Computers control machinery (CNC machines, robots) through CAM systems, ensuring accuracy, repeatability, and automation of production processes.

(iii) Quality Assurance: Computers analyze products using sensors and software (e.g., CMMs) to detect defects, ensure tolerances, and maintain consistency.

(iv) Material Handling: Computers manage inventory, automate guided vehicles (AGVs), and optimize logistics through software like ERP systems.

—

Question 3:

(a) Mention at least Six (6) spheres of human endeavour where computer technology is applied.

(b) Mention any Six (6) benefits of CAD.

Answer:

(a)

1. Engineering and manufacturing

2. Healthcare (e.g., medical imaging)

3. Education (e.g., e-learning platforms)

4. Entertainment (e.g., video games, CGI)

5. Transportation (e.g., autonomous vehicles)

6. Communication (e.g., internet, social media)

(b)

1. Improved design accuracy

2. Faster prototyping and iteration

3. Cost reduction in product development

4. Enhanced visualization (3D models)

5. Easier collaboration among teams

6. Integration with analysis tools (e.g., FEA)

—

Question 4:

(a) Write short notes on the following types of databases:

i. The individual database

ii. The company or shared database

iii. The distributed database

iv. The proprietary database

Answer:

i. Individual Database: Owned and used by a single person, typically for personal projects or small-scale applications.

ii. Company/Shared Database: Accessed by multiple users within an organization to centralize data and improve collaboration.

iii. Distributed Database: Data is stored across multiple locations or servers, enhancing accessibility and redundancy.

iv. Proprietary Database: Privately owned (e.g., Oracle, SQL Server), requiring licensing and offering specialized features.

—

Question 5:

(a) State three disadvantages of NC.

(b) With the aid of a sketch, differentiate between an open and a closed loop.

(c) Why do we sometimes use robots in manufacturing industries?

Answer:

(a)

1. High initial setup and programming costs.

2. Limited flexibility for design changes.

3. Requires skilled operators for maintenance.

(b) *(Note: Sketch not provided here, but description follows.)*

– Open Loop: No feedback system; actions are pre-programmed without adjustments (e.g., traffic light).

– Closed Loop: Uses feedback (sensors) to adjust operations in real-time (e.g., thermostat).

(c) Robots are used for:

1. Repetitive tasks (e.g., assembly lines).

2. Hazardous environments (e.g., welding).

3. High precision (e.g., surgical robots).

4. 24/7 productivity without fatigue.

—

Question 6:

(a) Explain the following types of NC systems:

i. Position or point-to-point system

ii. The continuous path system

(b) Define workstations.

(c) Differentiate between a workstation and a personal computer.

Answer:

(a)

i. Point-to-Point System: Moves tools to specific coordinates without controlling the path between points (e.g., drilling).

ii. Continuous Path System: Controls the tool’s entire path for complex shapes (e.g., milling contours).

(b) Workstation: A high-performance computer optimized for technical or scientific tasks (e.g., CAD/CAM).

(c) Differences:

– Workstation: More powerful, supports specialized software, used in industries.

– Personal Computer: General-purpose, lower cost, for everyday tasks.

—

Question 7:

(a) Write the full meaning of: CADD, CNC, CIM, CAPM, CAPP, CAQA.

(b) Report briefly on the development of a database for CAD/CAM.

Answer:

(a)

– CADD: Computer-Aided Design and Drafting

– CNC: Computer Numerical Control

– CIM: Computer-Integrated Manufacturing

– CAPM: Computer-Aided Production Management

– CAPP: Computer-Aided Process Planning

– CAQA: Computer-Aided Quality Assurance

(b) Database Development:

A CAD/CAM database stores design specs, material data, and machine instructions. It ensures data integrity, enables collaboration, and integrates with CAM for seamless production. Tools like SQL or PDM systems manage version control and accessibility.

—