ANWSER

ANWSER

—

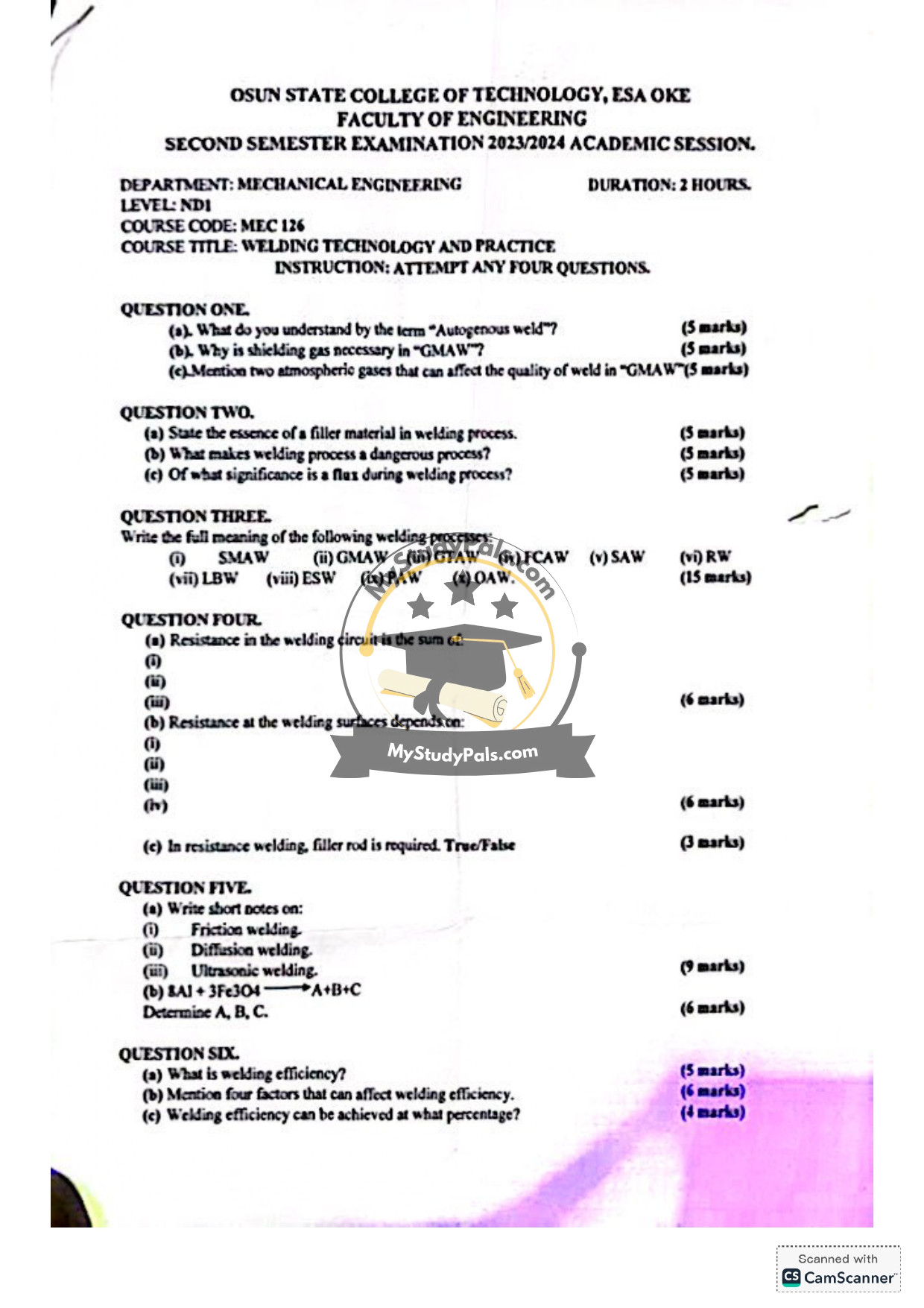

Question 1:

(a) Autogenous weld refers to a welding process where no filler material is used. The weld is created solely by melting the base metals together.

(b) Shielding gas is necessary in GMAW (Gas Metal Arc Welding) to protect the molten weld pool from atmospheric contamination (e.g., oxygen, nitrogen), which can cause defects like porosity and brittleness.

(c) Two atmospheric gases that can affect weld quality in GMAW are:

– Oxygen (O₂)

– Nitrogen (N₂)

—

Question 2:

(a) The filler material in welding is used to fill the joint gap, reinforce the weld, and ensure proper metallurgical properties.

(b) Welding is dangerous due to risks like electric shock, toxic fumes, UV radiation, fire/explosion hazards, and molten metal splatter.

(c) Flux cleans the weld area, prevents oxidation, and stabilizes the arc, improving weld quality.

—

Question 3:

(i) SMAW – Shielded Metal Arc Welding

(ii) GMAW – Gas Metal Arc Welding

(iii) GTAW – Gas Tungsten Arc Welding

(iv) FCAW – Flux-Cored Arc Welding

(v) SAW – Submerged Arc Welding

(vi) RW – Resistance Welding

(vii) LBW – Laser Beam Welding

(viii) ESW – Electroslag Welding

(ix) PAW – Plasma Arc Welding

(x) OAW – Oxy-Acetylene Welding

—

Question 4:

(a) Resistance in the welding circuit is the sum of:

(i) Electrode resistance

(ii) Workpiece resistance

(iii) Contact resistance

(b) Resistance at the welding surfaces depends on:

(i) Surface cleanliness

(ii) Pressure applied

(iii) Material type

(iv) Temperature

(c) False (Filler rod is not used in resistance welding).

—

Question 5:

(a) Short notes:

(i) Friction welding: Joins materials using mechanical friction and pressure, generating heat without melting.

(ii) Diffusion welding: Bonds materials under high pressure and temperature, allowing atomic diffusion.

(iii) Ultrasonic welding: Uses high-frequency vibrations to weld thin materials (e.g., plastics, metals).

(b) A = 8Fe, B = Al₂O₃, C = Heat (Reaction: Thermite welding).

—

Question 6:

(a) Welding efficiency measures how effectively welding energy is used to produce a sound weld.

(b) Factors affecting welding efficiency:

– Skill of the welder

– Equipment condition

– Material preparation

– Environmental conditions

(c) Welding efficiency is typically 60–95%, depending on the process and conditions.

—