ANWSER

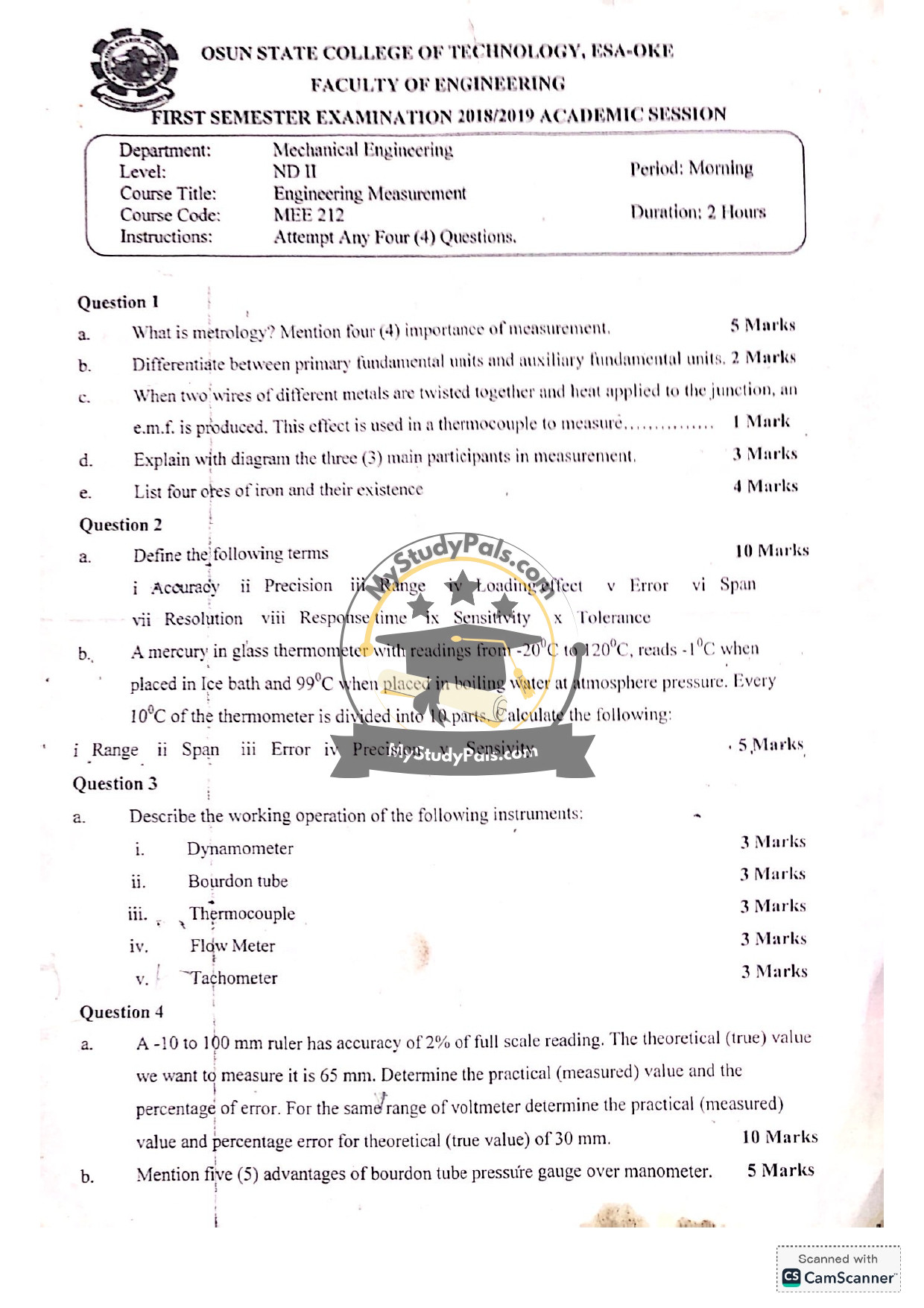

Question 1:

a. Metrology is the science of measurement.

Four importance of measurement:

1. Ensures quality control in manufacturing.

2. Facilitates standardization and interchangeability of parts.

3. Enables accurate scientific research and experimentation.

4. Supports compliance with regulatory and safety standards.

b. Primary fundamental units are the base units of measurement (e.g., meter, kilogram, second).

Auxiliary fundamental units are derived from primary units and used for specialized measurements (e.g., newton, joule).

c. The described effect is the Seebeck effect, used in thermocouples to measure temperature.

d. Three main participants in measurement:

1. Measurand: The physical quantity being measured (e.g., temperature).

2. Sensor/Instrument: The device that detects the measurand (e.g., thermometer).

3. Observer/User: The person or system interpreting the measurement.

*(Diagram not provided here, but it would show these three components interacting.)*

e. Four ores of iron and their existence:

1. Hematite (Fe₂O₃): Found in sedimentary rocks.

2. Magnetite (Fe₃O₄): Found in igneous and metamorphic rocks.

3. Limonite (FeO(OH)·nH₂O): Found in weathered iron deposits.

4. Siderite (FeCO₃): Found in sedimentary mineral beds.

—

Question 2:

a. Definitions:

i. Accuracy: Closeness of a measurement to the true value.

ii. Precision: Consistency of repeated measurements.

iii. Range: Difference between the highest and lowest values measurable.

iv. Loading effect: Disturbance caused by the measuring instrument on the system.

v. Error: Deviation between measured and true values.

vi. Span: Difference between the upper and lower limits of an instrument.

vii. Resolution: Smallest detectable change in measurement.

viii. Response time: Time taken for an instrument to react to a change.

ix. Sensitivity: Ratio of output change to input change.

x. Tolerance: Permissible deviation from a specified value.

b. Calculations for the thermometer:

i. Range: -20°C to 120°C (given).

ii. Span: 120°C – (-20°C) = 140°C.

iii. Error: At 0°C (ice bath), error = -1°C – 0°C = -1°C.

At 100°C (boiling water), error = 99°C – 100°C = -1°C.

iv. Precision: Determined by the smallest division (10°C/10 = 1°C).

v. Sensitivity: Change in output per unit input (e.g., 1°C per division).

—

Question 3:

a. Working operations:

i. Dynamometer: Measures force or torque by balancing against a known force.

ii. Bourdon tube: Converts fluid pressure into mechanical displacement via a curved tube.

iii. Thermocouple: Generates a voltage proportional to temperature difference between junctions.

iv. Flow Meter: Measures fluid flow rate using mechanisms like turbines or differential pressure.

v. Tachometer: Measures rotational speed (RPM) using mechanical or electronic sensors.

—

Question 4:

a. Calculations for the ruler:

– Accuracy: 2% of full scale (100 mm) = ±2 mm.

– Practical value for 65 mm: 65 ± 2 mm (i.e., 63–67 mm).

– Percentage error for 65 mm: (2/65) × 100 ≈ 3.08%.

– For 30 mm true value: Practical value = 30 ± 2 mm (28–32 mm).

Percentage error = (2/30) × 100 ≈ 6.67%.

b. Advantages of Bourdon tube over manometer:

1. Compact and portable.

2. No risk of fluid leakage (if sealed).

3. Higher durability for industrial use.

4. Easier to read with a direct pointer display.

5. Suitable for high-pressure measurements.

—